Investigation of stochastic nucleation using microfluidics

Droplet based microfluidic systems have recently emerged as a powerful experimental tool for investigating fundamentals of crystallization processes because they offer a variety of original features that permit:

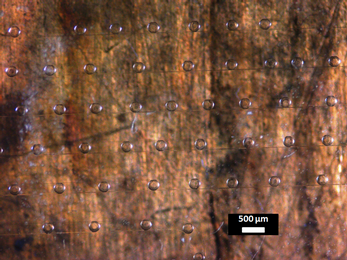

- High-throughput data acquisition using crystallization assays with volumes in the pico- to microliter range;

- Minimization of solution impurities, foreign surfaces and differences of initial and boundary conditions among experiments’ repetitions;

- Assessment of new experimental conditions to investigate crystallization, with no turbulence, no or little gravity effect, confinement, and large surface to volume ratio;

- Rapid screening of many different systems and their behavior using small amounts of both solute and solvent;

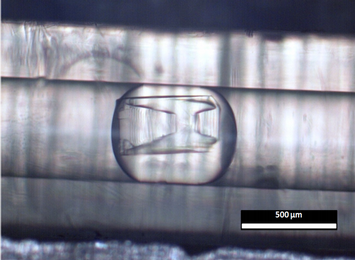

- Design of specific kinetic routes using excellent control of mass and heat transfer due to the reduction of the length scales and on-chip integration of sensors and actuators;

Crystallization in small volumes is a topic of interest due to the stochastic nature of nucleation. Indeed, the induction time, i.e. the time when the first crystals are detected, varies even in identical repetition of experiments. Microfluidic devices offer the advantage that hundreds of monodisperse droplets can be formed; each droplet is considered an individual crystallizer, resulting in a great number of simultaneous experiments. This large amount of data can be used to obtain reliable statistics for studying the stochastic behavior of primary nucleation.