Precipitation and stabilization of particles

In this project, the precipitation and controlled stabilization of structured micro-particles is being studied. Precipitation in static micro-mixers (e.g. Y-mixers) is a commonly used process in production of micro- and nano- particles [1]. Morphology of these particles is often an important factor, as it has an impact on the efficiency of the downstream product handling (i.e. filtering or drying) as well as on the crystal’s actual physical properties (i.e. dissolution kinetics or bioavailability) [2]. One way of controlling this crucial parameter is by using additives (i.e. preventing agglomeration or inhibiting growth on specific crystal facets). In this project we are concentrating on correctly describing all the phenomena influencing the system and including them in a model in order to obtain a tool, which would allow for a model-based design of a process.

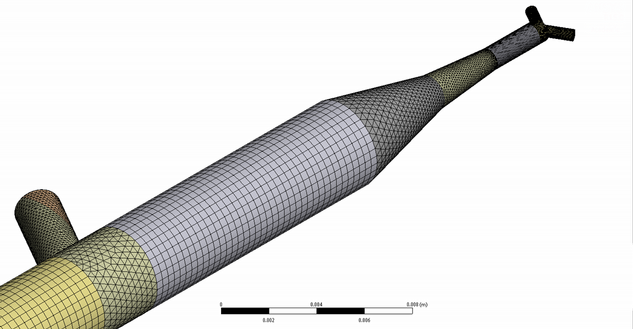

In the investigated process, due to very high supersaturations reached, the particle formation kinetics can be so fast, that mixing might become the limiting factor, thus making the process and the properties of the final crystalline product dependent on the mixing conditions [3][4]. Applying a model-based approach to designing continuous precipitation processes without taking this into account might lead to an inaccurate model. In this project, in order to obtain a model with good predictive capabilities, a comprehensive approach has been chosen. In our model we are including nucleation, growth, agglomeration, aggregation, additive effects and mixing – all at the same time. In order to obtain the experimental data necessary for the estimations of model parameters, as well as to validate the model, a plant has been build capable of running continuous precipitation for a wide range of compounds with an additional inlet for an additive feed. Being able to control the process conditions precisely, an effect of various parameters can be investigated.

At the end, together with the experimental data and by employing CFD modelling, we are hoping for obtaining a tool which would help design robust processes quicker and more efficiently.

References

- external page call_made 1. Lindenberg, C.; Mazzotti, M. Chem. Eng. Sci. 2009, 64, 4286–4294

- external page call_made 2. Salvalaglio, M.; Vetter, T.; Giberti, F.; Mazzotti, M.; Parrinello, M. J. Am. Chem. Soc. 2012, 134, 17221–17233

- external page call_made 3. Baldyga, J.; Makowski, Ł.; Orciuch, W. Ind. Eng. Chem. Res. 2005, 44, 5342–5352

- external page call_made 4. Lindenberg, C.; Schöll, J.; Vicum, L.; Mazzotti, M.; Brozio, J. Chem. Eng. Sci. 2008, 63, 4135–4149