Membrane-based gas separation processes

The new Swiss energy strategy has prompted the establishment of several research projects on energy, namely, the Swiss Competence Centers for Energy Research (SCCER). Within this framework, the SCCER-Efficiency in Industrial Processes aims at improving the energy efficiency of the industrial sector. Besides enhancing the process efficiency with direct energy-efficiency measures, such as heat recovery and energy integration, indirect measures, involving process modifications, open doors to significant energy savings.

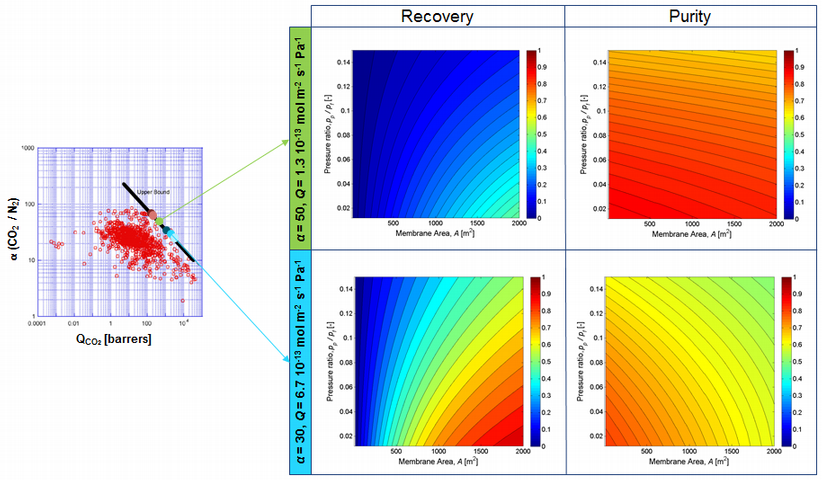

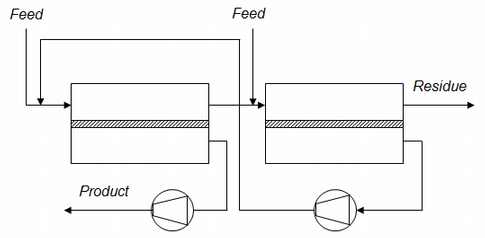

In this context, membrane-based gas separation has a great innovation potential, which can enable the industry to reach its energy efficiency targets. The modular nature of membrane operations is intrinsically fit for process intensification, and this versatility might be a decisive factor to impose membrane processes in most gas separation fields [1]. In this direction, the process configuration is a fundamental aspect, in addition to high performance materials, to make membrane technology competitive with current state-of-the-art technologies.

Furthermore, the opportunities for the integration of membrane gas separation units in hybrid systems should be investigated for the intensification of industrial processes.

The research activity aims at a systematic analysis of the separation performance, as well as membrane area and energy requirements of membrane gas separation processes. As a result, optimal configurations and convenient operational conditions can be identified for membrane technology compared to consolidated operations such as pressure swing adsorption or cryogenic distillation.