Enantiomeric resolution by Viedma Ripening

Chirality is a ubiquitous property of nature, and, the obtainment of highly chirally pure products is particularly pressing and demanding in pharmaceutical industry. Chiral molecules, although sharing practically all physico-chemical properties, such as solubility in achiral media, melting and boiling point, behave drastically different if chiral receptors, such as biological proteins, are involved. A notorious case is that of thalidomide: one of the racemic components has sedative effects, whereas the other is highly teratogenic.

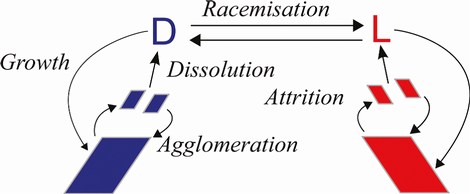

Crystallisation is one of the techniques exploitable to separate racemic molecules forming so-called conglomerate systems, i.e. a system where the two different enantiomeric species crystallise always separately. About 5 to 10 % of known racemic substances are known to obey such rule. A limit of the conventional method is the low yield of the process: from a mixture with no initial enantiomeric excess (ee 0%), only 50% of the final crystals are of the targeted product. Hence, recycles and chemical racemisation are needed to be integrated in the process to increment the yield. Recently, a new mechanism has been discovered, which integrates both crystallisation and racemisation for conglomerates in a single process: the attrition-enhanced chiral resolution, also termed Viedma Ripening, in honour of its discoverer [1]. The main advantage is that, by coupling racemisation with crystallisation, a theoretical yield of 100% can be reached. The fundamental mechanisms underlying the attrition enhanced resolution have been studied in our group (Figure 1) [2] and can be summarised as: racemisation, growth and dissolution (both dependent on the particle size), attrition, and agglomeration. Similar results can be achieved with a modified Viedma ripening, where attrition is replaced by temperature cycles [3].

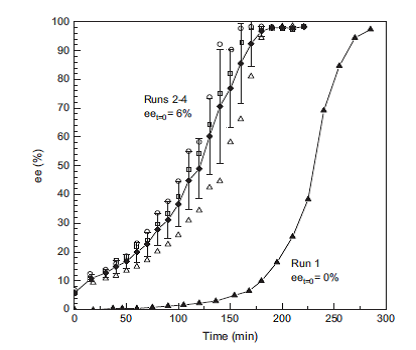

Our research concentrates to further develop Viedma ripening potential in view of industrial applications. On the one hand, we aim to provide a mathematical model for both simulating the process in silico and thus optimising. On the other hand, we also explore alternative techniques to speed up the deracemisation process, e.g. by substituting the mechanical grinding and temperature cycles, normally used independently, with High-Pressure Homogenisation (HPH) [4], which combines both features, effectively accelerating the process from days to hours (Figure 2).

References

- external page call_made 1. Viedma, C. Phys. Rev. Lett. 2005, 94, 065504

- external page call_made 2. Iggland, M.; Mazzotti, M. Crys. Growth Des. 2012, 12 1498-1500

- external page call_made 3. Suwannasang, K. ; Flood, A.; Rougeot, C.; Coquerel, G. Crys. Growth. Des. 2013, 13, 3498-3504

- external page call_made 4. Iggland, M.; Fernández-Ronco, M. ; Senn R.; Mazzotti, M. Chem. Eng. Sci. 2014, 111, 106-111